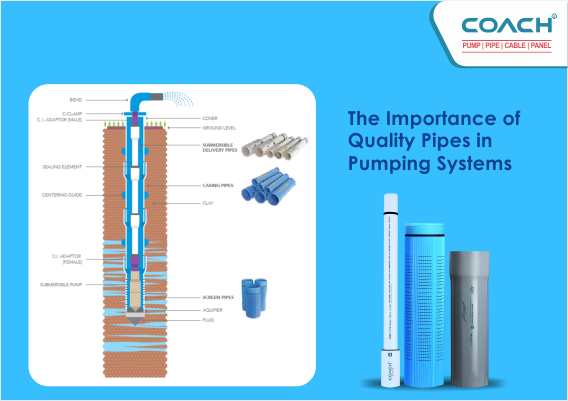

The Importance of Quality Pipes in Pumping Systems

- March 10, 2023

- Category :Pipes

Introduction:

When it comes to designing an efficient pumping system, many factors come into play, and one crucial aspect often overlooked is the quality of pipes used. The pipes in a pumping system play a vital role in ensuring smooth and reliable water flow. In this blog post, we will explore the importance of using high-quality pipes in pumping systems and how they contribute to the overall efficiency and longevity of the system.

- Optimal Flow Rate and Pressure:

High-quality pipes are designed to have smooth interiors and precise dimensions, resulting in minimal friction losses during water flow. Friction losses can significantly impact the flow rate and pressure in a pumping system. Using low-quality or undersized pipes can lead to pressure drops, reduced flow rates, and decreased pump efficiency. By investing in quality pipes, you can ensure that water flows smoothly and efficiently, maximizing the performance of your pumping system.

- Reduced Energy Consumption:

Efficient pipe materials, such as those with low friction coefficients and excellent hydraulic properties, can help minimize energy losses in a pumping system. When pipes have smooth interiors and are properly sized, the pump doesn’t have to work as hard to overcome friction and maintain desired flow rates. As a result, less energy is consumed, leading to cost savings and reduced environmental impact. Quality pipes contribute to the overall energy efficiency of the pumping system.

- Resistance to Corrosion and Wear:

In pumping systems, the transported water can contain various chemicals, minerals, or contaminants that can corrode or damage pipes over time. High-quality pipes are often made from corrosion-resistant materials like stainless steel, PVC, or HDPE (high-density polyethylene). These materials offer excellent resistance to rust, chemicals, and abrasion, ensuring the longevity of the pipes. Choosing quality pipes reduces the risk of leaks, bursts, or pipe failures, leading to fewer maintenance issues and longer service life.

- Minimized Leakage and Water Loss:

Water leakage in a pumping system not only wastes a valuable resource but also affects the efficiency of the entire system. Low-quality pipes are more prone to leaks due to their inferior construction or inadequate sealing. Quality pipes, on the other hand, are manufactured with precision and have better joint integrity, minimizing the chances of leaks and water loss. By investing in quality pipes, you can ensure that water is effectively delivered to its intended destination, reducing wastage and optimizing the system’s performance.

- Environmental and Health Considerations:

Using quality pipes in a pumping system is not only beneficial for the efficiency and longevity of the system but also for the environment and human health. Inferior pipes may contain harmful substances like lead, which can contaminate the water supply. High-quality pipes are manufactured according to rigorous standards and regulations, ensuring they are safe for transporting potable water. By using quality pipes, you contribute to a healthier and safer water supply for both humans and the environment.

Final Thoughts:

The importance of quality pipes in pumping systems cannot be overstated. From optimizing flow rate and pressure to reducing energy consumption, minimizing leaks, and ensuring environmental and health safety, high-quality pipes are essential for the efficiency and longevity of the system. When designing or upgrading a pumping system, it is crucial to invest in pipes made from corrosion-resistant materials, with precise dimensions and smooth interiors. By prioritizing quality pipes, you can reap the benefits of a well-functioning, reliable, and sustainable pumping system that meets your water transportation needs for years to come.