Know Your Submersible Pump from Inside Out

- January 1, 2023

- Category :Submersible Pump & Motor

Introduction:

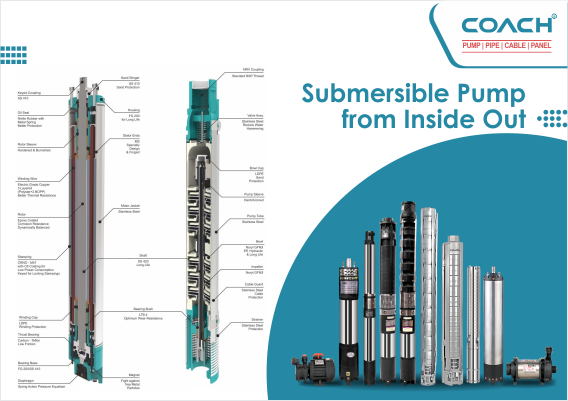

Submersible pumps are reliable and efficient devices widely used for various applications, including water supply, irrigation, drainage, and more. Understanding the internal components and functioning of a submersible pump can help you make informed decisions when choosing, operating, and maintaining these essential devices. In this blog post, we will take a closer look at the key components and workings of a submersible pump to enhance your knowledge and ensure optimal performance.

- Motor:

The motor is the heart of a submersible pump and is responsible for driving the impeller. Submersible pump motors are designed to operate underwater and are typically sealed to prevent water entry. They are hermetically sealed to provide insulation and protect against external elements. The motor converts electrical energy into mechanical energy, driving the impeller to create the necessary water flow.

- Impeller:

The impeller is a crucial component that creates the water flow within the pump. It consists of curved blades or vanes that push the water as the impeller rotates. The design of the impeller determines the pump’s flow rate and head capacity. Different impeller designs, such as radial flow, axial flow, or mixed flow, are used depending on the specific application requirements.

- Pump Casing:

The pump casing, also known as the volute, houses the impeller and directs the water flow. It is typically made of durable materials such as cast iron, stainless steel, or thermoplastic. The shape of the pump casing is designed to increase the pump’s efficiency by minimizing energy losses and maintaining a smooth flow path for the water.

- Shaft and Seals:

The shaft connects the motor to the impeller and transfers rotational energy. It is made of high-quality materials such as stainless steel to withstand the forces and pressures generated by the pump. Seals, such as mechanical seals or lip seals, are used to prevent water leakage along the shaft. Proper seals ensure the pump remains watertight and efficient.

- Control Box:

In some submersible pumps, a control box is used to house electrical components, including capacitors, relays, and control circuitry. The control box provides protection and facilitates the control and monitoring of the pump. It enables features such as motor starting, overload protection, and automatic pump operation.

Understanding the workings of a submersible pump is essential for proper operation and maintenance. Here are some additional tips to ensure optimal performance:

- Select the right pump size and type based on the specific application requirements.

- Regularly inspect and clean the pump to prevent debris buildup and clogging.

- Follow manufacturer guidelines for pump installation and electrical connections.

- Monitor motor temperature and electrical parameters to ensure safe operation.

- Conduct regular maintenance, including lubrication, seal replacement, and motor servicing, as recommended by the manufacturer.

By knowing the internal components and functioning of your submersible pump, you can make informed decisions, troubleshoot issues effectively, and ensure the longevity and efficiency of the pump.

Wrapping up!

A submersible pump is a complex device with various components working together to provide efficient water pumping. Understanding the motor, impeller, pump casing, shaft, seals, and control box can help you make informed decisions, properly operate the pump, and perform necessary maintenance. By enhancing your knowledge of submersible pumps from the inside out, you can optimize performance, increase reliability, and achieve efficient water management in your applications.

A submersible pump has to be installed along with multiple components and it is evident that each component plays an equally important role in ensuring the flawless function of a submersible pump. You may use this list to install a submersible pump along with all essential parts. Was this article helpful to you? Find more informative articles at Coach Pumps.